POLYETHYLENE COATING

THIN COATINGS AT LOWER COSTS

ABOUT POLYETHYLENE POWDERS

- Outdoor Furniture

- Playground equipment

- Refrigerator shelves

- Sporting goods

- Wire grates and guards

- Bike racks

FREQUENTLY ASKED QUESTIONS ABOUT POLYETHYLENE COATING

Polyethylene (PE) plastic is familiar to many from its popularity as a packaging material for food and many other products, but polyethylene also makes an ideal powder coating with varieties suitable for indoor and outdoor use. Answers to common questions about polyethylene coatings are provided below.

-

What is polyethylene coating?

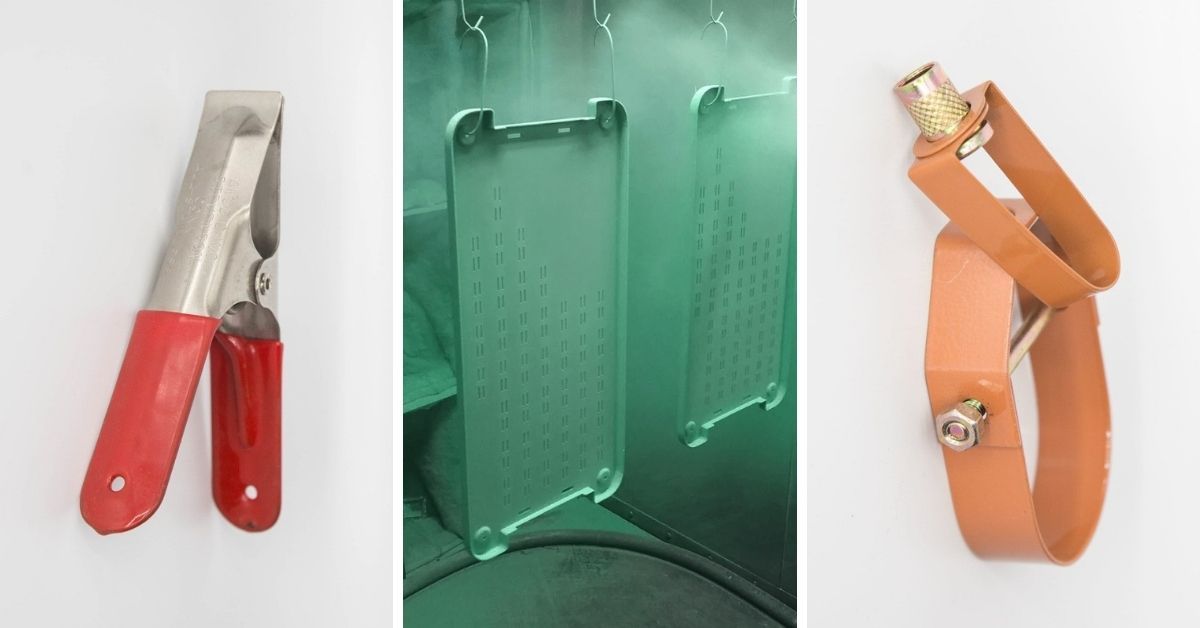

Produced most commonly in low-density (LDPE) and high-density (HDPE) types, polyethylene is part of the polyolefin family of thermoplastics. As a powder coating, changes in formulations offer a material suited to nearly any application and industry. Coatings are typically 12-40 mils (.012-.04 inches).

-

What makes polyethylene a desirable coating material?

One of polyethylene coating's most valuable qualities is its resistance to cracking under stress (ductility), but PE coating has more to offer, including:

- Abrasion and impact resistance

- Chemical and corrosion resistance

- Non-yellowing

- Low-temperature tolerance

- Durability

- Food-grade rating

- UV-tolerance (some formulations)

-

What industries use polyethylene powder coatings?

While polyethylene coatings are suitable for a wide range of applications, their approval for food-grade uses makes them especially popular for coating wire racks such as in refrigerators, dishwashers, freezers, and other food-storage and household environments. Polyethylene is durable enough to perform well in those applications as well as such diverse uses as landscaping equipment, railings, and sporting goods.

-

Is polyethylene coating safe?

Polyethylene is approved by multiple agencies for food-grade use, making it extremely safe. As such, it contains no BPA, phthalates, heavy metals, halogens, or other toxic components, and requires no solvents or VOCs to apply.

-

What colors are available for polyethylene coating?

Polyethylenes can be transparent to opaque, and many varieties are available in a spectrum of stock and custom colors.

LEARN MORE WITH OUR BLOGS

HAVE QUESTIONS?

Thinking of starting a project and want to know if we're the right fit to work with you? We would love to answer any question that you may have. Precision Dip Coating is located on 176 Chase River Rd, Waterbury, CT 06704, United States and can help you step in the right direction with your project. Additionally, you can email sales@precisiondipcoating.com for more information.

ISO 9001:2015 Certified

ABOUT

SERVICES

CONTACT US

CONTACT USThe information on this website is for general information purposes only. This information is not intended to create, and receipt or viewing does not constitute, a manufacturer and client relationship. Precision Dip Coating is licensed & insured for the job. Call 203-805-4564. Email with any questions you may have regarding this website, or anything associated with it.

All Rights Reserved. This website was designed, SEO optimized, and marketed by DeveloMark.