How Long Does Powder Coating Last?

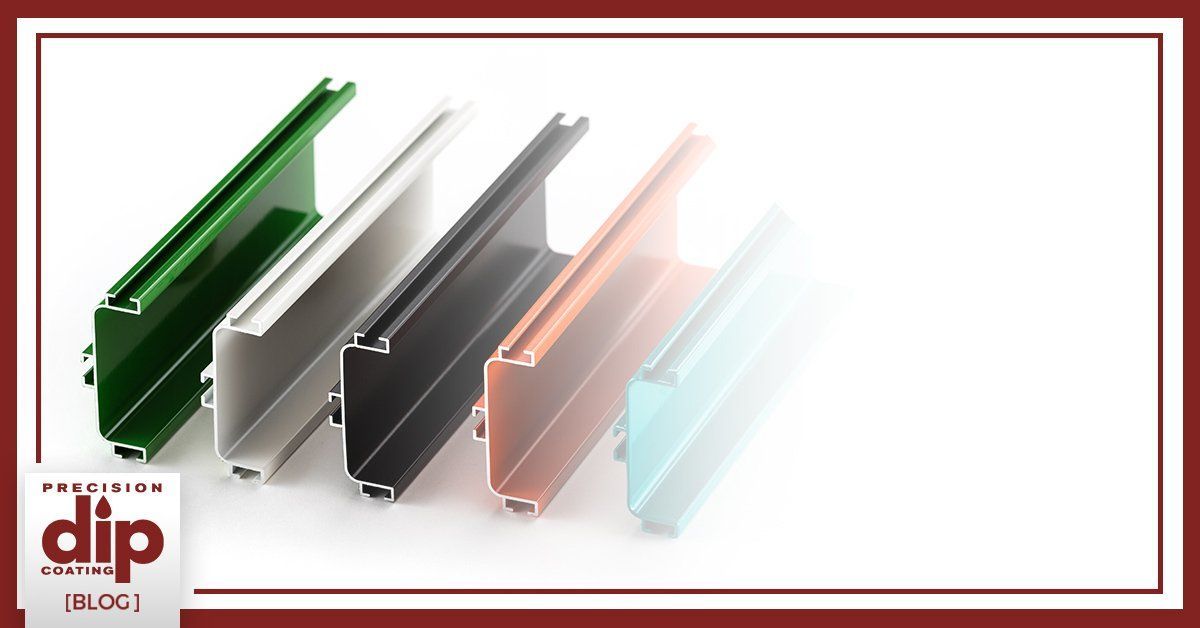

The powder coating process creates a smooth, extremely durable and protective finish. It is done by applying an electrostatically charged, powdered mixture of plastic resin and additives to a surface, usually metal, and heat-cured to form a strong bond resulting in an extremely durable finish.

How Long Does It Last?

Most powder coating applications last for 15-20 years. These coatings are highly resistant to weather, chemicals, and corrosion, and offer electrical insulation, and vibration and sound deadening benefits.

What Lengthens the Lifespan of Powder Coating?

Powder coatings have naturally long lives due to the strength of the electrostatic bond between the paint and substrate. Appropriate pre-treatment before coating and care afterwards can help ensure coatings have the longest possible lifespan.

Surface Pre-Treatment

As with any painting or coating project, properly preparing the surfaces to be powder coated will enhance both quality and durability. Pre-treatment can include:

- Cleaning - Generally done with acids or solvents by spraying, wiping, pressure-washing, or dipping, to remove dirt, oil, waxes, and grime.

- Shot-Blasting - Like sandblasting, particles of sand, shot, walnut shells, or other material are blown with force at surfaces to remove scale, rust, and most surface dirt and oils.

- Etching or Phosphating - These pretreatments help to prevent corrosion and improve a coating's adherence.

- Primer - A primer coat can be applied to enhance the coating's ability to adhere.

Post-Coating Care

In general, only occasional cleaning is needed for powder-coated surfaces. Non-abrasive, solvent-free cleaning materials should be used.

What Shortens the Lifespan of Powder Coating?

Naturally, poor pre-treatment and care can cause powder coatings to degrade more rapidly than they should. Other environmental conditions and exposures can also shorten their lifespans, including:

- Environment & Weather - Exposure to salt water, blowing sand, and other harsh elements of weather and nature can wear down coatings more quickly.

- Hazardous Exposure -Contact with industrial and other chemicals and compounds, including gasoline, xylene, and caustics, can affect the durability of powder coating.

- Abrasive Cleaners - Use of abrasive cleaners such as scouring pads, steel wool, and wire brushes as well as many solvents can affect powder coating's longevity.

At Precision Dip Coating, we strive to provide the highest quality coating, molding, and manufacturing services to exceed your needs within your budget, all at our own facility.

Contact us today to learn more about our powder coating and other plastics and manufacturing solutions or to request a quote.