LEADING STERILIZATION COATING MANUFACTURERS

Elevating Safety Through Advanced Sterilization Solutions

Our specialized sterilization coatings are designed to meet the stringent demands of industries requiring utmost cleanliness and germ-free environments. Learn how our advanced solutions provide durable, effective protection against contamination, ensuring your products perform safely and efficiently in critical applications.

What Does Sterilization Do?

Nylon coated products provide a durable finish that will withstand the repetitive sterilization cycles that are so critical to operating rooms and other environments where protection from bacteria and other living organisms is needed. Surgical instrument trays, cases, and other medical equipment must be thoroughly sterilized to protect both healthcare workers and their patients from harm. Typically, this equipment is sterilized in an autoclave, with exposure for up to half an hour of pressurized steam at temperatures ranging from 121 °C to 135 °C (250 °F to 275 °F). Nylon sterilization coating is up to that challenge.

Benefits of Sterilization Coating

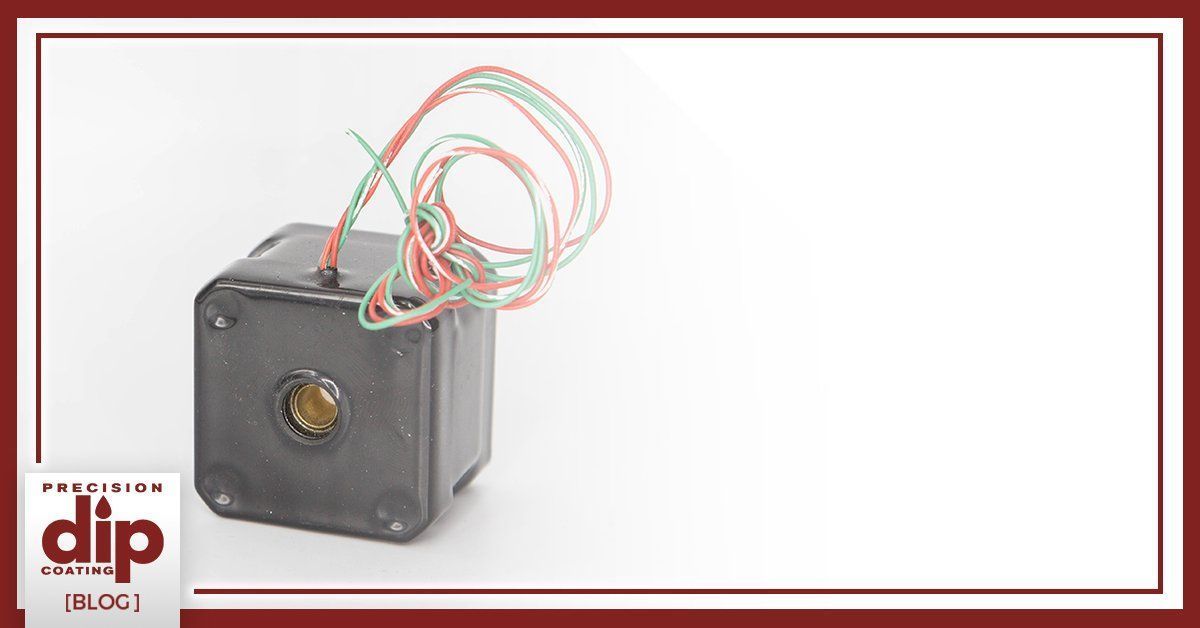

Commonly applied to equipment for the healthcare industry, sterilization coating provides a protective layer over vulnerable stainless steel or aluminum, improving their ability to perform more safely for a longer time. Nylon,

or

polyamide coatings are applied by electrostatic spray or fluidized bed techniques, in thicknesses ranging from .005 to .04 inches, and offer numerous benefits, including:

Contact Us Today

At Precision Dip Coating, our nylon sterilization coating equipment, processes, and results are industry validated, and we are proud to be among the first plastic coating companies to have achieved this level of performance. Contact us today to explore our sterilization coating services and other spray and dip coating solutions.

Contact Us

Contact Us

Related Services

For more information about our manufacturing services, call us at 203-805-4564 or visit ourcontact page.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Frequently Asked Questions

What is sterilization coating made of?

Sterilization coating is applied with a type of synthetic polyamide (nylon).

How thick is sterilization coating?

Thin, even, smooth sterilization coatings typically range from about .005" (5 mils) to .04" (40 mils).

What makes sterilization coating effective?

Nylon offers a combination of qualities that make it particularly well suited for sterilization applications, including:

- Extreme smoothness

- 100% encapsulation

- Superior durability

- Non-toxic material

- Excellent longevity

- High heat tolerance

- Non-absorbent

- High pressure tolerance

- Chemical, moisture, and corrosion resistant

How is sterilization coating applied?

As with most powder coatings, sterilization coating can be applied by electrostatic spray or through fluidized bed techniques. Choosing between these application methods depends mainly on the shape and structure of the product being coated, and desired coating thickness.

What substrates are suitable for sterilization coating?

Because of the temperatures needed to cure sterilization coatings, substrates must be able to withstand that exposure. Typical substrates are made from various steel and aluminum alloys.

What industries use sterilization coating?

The medical industry uses sterilization coating most often, typically for surgical instrument cases and trays and other medical equipment which comes into direct patient contact. Truly, any industry requiring nylon's unique combination of physical, thermal, and mechanical characteristics will benefit from its many advantages.

Our Blog