coating for the aerospace industry

Protection For Extremes

When it comes to aerospace safety, there is zero room for error. Each and every part of an aircraft needs to be designed, manufactured, assembled and maintained with the highest safety standards. Proper coating of parts used in airplanes, jets, helicopters and other aircrafts supports these strictest of guidelines. At Precision Dip Coating, we offer protection for surfaces and components in the aerospace industry.

Common Plastic Coated Parts in The Aerospace Industry

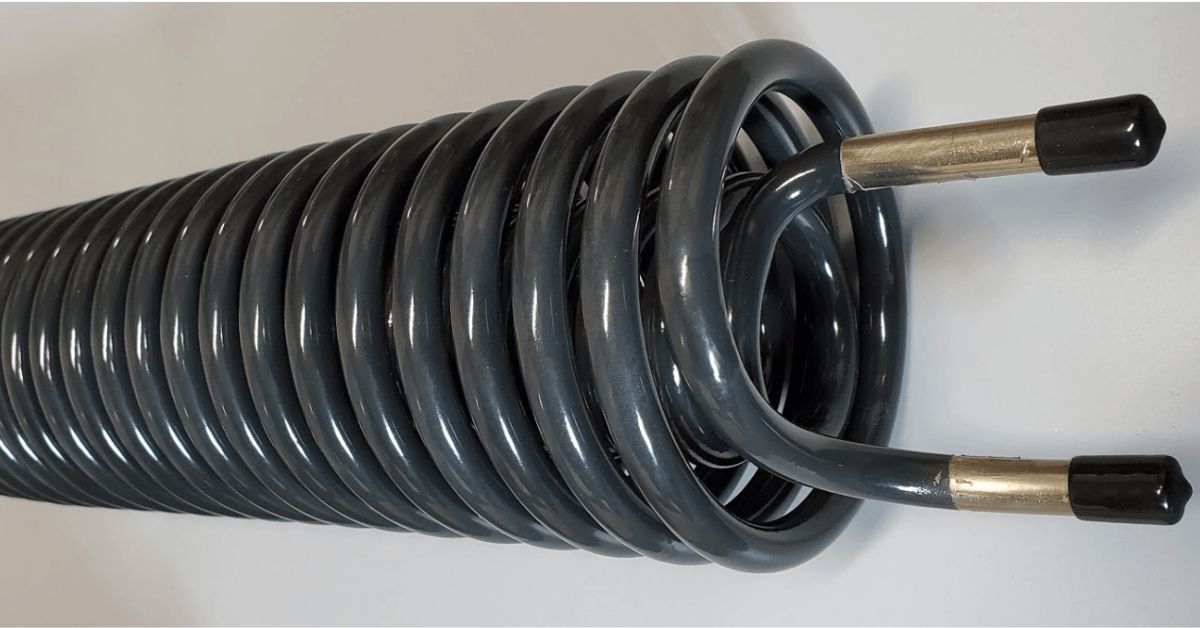

In the aerospace industry, the use of plastic coatings is critical for enhancing the functionality, safety, and longevity of various components. These coatings not only improve the physical properties of parts but also contribute significantly to the overall performance and durability of aerospace technology. Here are some of the common parts in the aerospace industry that benefit from plastic coatings:

Industry Specifications

Our aerospace coatings adhere to (but are not limited to) the following industry specifications:

Challenges That Coatings Solve For The Aerospace Industry

Plastic coatings for the aerospace industry must withstand and protect vulnerable parts and equipment against extreme temperatures, heavy wear, and other hazards of flight and space conditions. Plastic coatings prolong part longevity and resilience and help to ensure critical components are adequately lubricated.

Contact Us Today

Elevate the safety and durability of your aerospace components with Precision Dip Coating's expert services. We specialize in applying coatings that enhance part longevity, ergonomics, and resistance to environmental wear, ensuring your aerospace components perform at their best. For details on our product range or process specifics, don't hesitate to

contact us.

Contact Us

Contact Us

Related Services

For more information about our manufacturing services, call us at 203-805-4564 or visit our contact page.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Frequently Asked Questions

What are the most high-performance plastic coatings?

Which powder coatings help reduce friction most effectively in the aerospace industry?

Halar®, a material similar to Teflon, and more traditional nylon are coatings that are both well-known for being extremely smooth, substantially reducing friction in numerous applications.

What parts are commonly plastic coated in the aerospace industry?

Among the many parts commonly coated are:

- Handles, control wheels, throttles, and other parts which benefit from softer, better ergonomics for improved comfort and safety

- Trim and exterior parts which require minimized drag and UV resistance

- Components which benefit from reduced wear and friction, as well as resistance to chemicals, corrosives, oxidation, moisture, abrasion, and other environmental hazards

What standards do our aerospace coatings meet?

Our polymer coatings are compliant with numerous aerospace and aviation standards, including:

- Mil P-20689

- Mil AA-59464

- Mil-I-15265

- PS 13511

- Lockheed Martin FPS-1021A

- FAR Part 25 853

What challenges does the aerospace industry solve with plastic coatings?

Plastic coatings for the aerospace industry must withstand and protect vulnerable parts and equipment against extreme temperatures, heavy wear, and other hazards of flight and space conditions. Plastic coatings prolong part longevity and resilience and help to ensure critical components are adequately lubricated.

Our Blog