epoxy Coating Services inPrecision Dip Coating

Enhancing Durability and Performance

At Precision Dip Coating, we specialize in providing top-tier epoxy coating solutions, designed to significantly enhance the durability, resistance, and performance of your products. Epoxy coatings are renowned for their exceptional adhesive properties, robust protection against corrosion, chemical resistance, and superior finish. Ideal for a wide array of applications across various industries, our epoxy coating services are tailored to meet the unique needs of each client, ensuring optimal results every time.

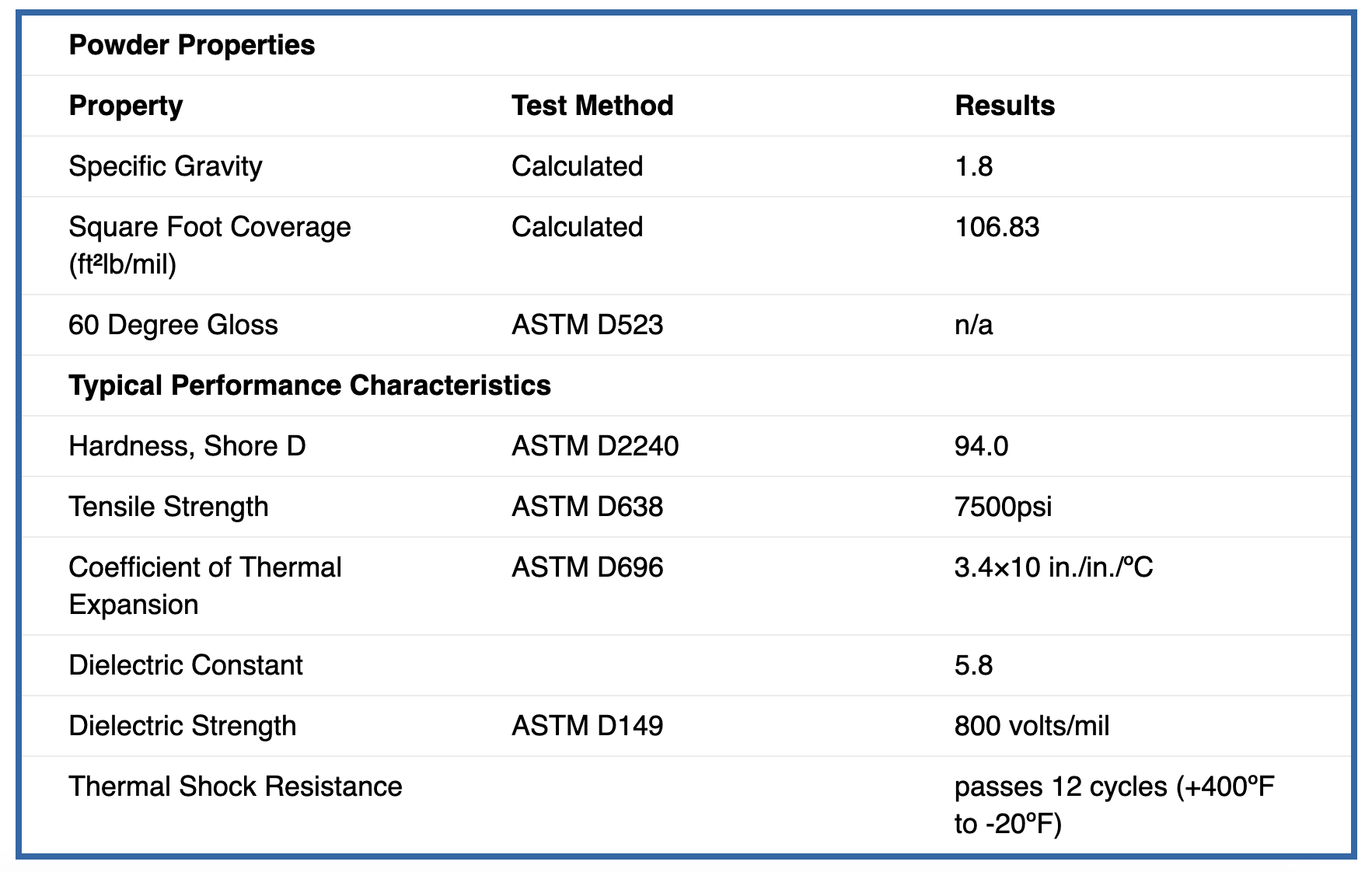

Epoxy Coating Performance Characteristics

Why Choose Epoxy Coating?

Discover the transformative power of epoxy coating, a premier solution that offers both protection and beauty for a wide range of applications.

Our Epoxy Coating Process

Our refined epoxy coating process begins with thorough surface preparation, ensuring optimal adhesion for a smooth, uniform coating. Precision application follows, using state-of-the-art techniques for even coverage. The process concludes with a controlled curing phase, solidifying the coating's durability and resistance. At every step, from consultation to final inspection, our team ensures the finished product meets our high standards of quality and performance, delivering unmatched durability and aesthetic appeal to every coated item.

Applications of Epoxy Coating

Epoxy coatings are incredibly versatile, making them suitable for a vast range of applications, including but not limited to:

Get Started with Precision Dip Coating

Elevate the durability, appearance, and performance of your products with our professional epoxy coating services.

Contact Precision Dip Coating

today to discuss how our epoxy solutions can benefit your project. Let us help you achieve the perfect finish that stands the test of time.

Contact Us

Contact Us

Related Services

For more information about our manufacturing services, call us at 203-805-4564 or visit ourcontact page.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Frequently Asked Questions

What applications are epoxy coatings most often used for?

Popular uses of epoxy coatings include gas and oil pipelines, electrical equipment, and consumer goods. Qualities that make epoxy especially useful include its:

- Excellent dielectric insulation rating

- Extreme resistance to chemicals and corrosion

- Proven durability

- Superior adhesion to substrates

- Powerful protection for parts and products when UV exposure isn't a concern

When is epoxy a poor coating choice?

If epoxy has one major weakness, it's found in its poor tolerance for UV exposure, which causes a permanent yellow or amber discoloration and chalky surface. UV stabilizers and absorbers can postpone these effects, but not completely prevent them.

Is epoxy a long-lasting powder coating?

One of the most durable powder coating treatments available, epoxy coatings can last for decades, even with regular use.

How are epoxy coatings applied?

Epoxy coatings can be applied by electrostatic spray coating or fluidized bed techniques, both resulting in an even, resilient, durable protective coat.

Can epoxy coatings be colored?

Epoxy coatings can be applied in a variety of colors, but, as mentioned above, even the best additives can't completely prevent epoxy coatings from yellowing a bit eventually, with UV light exposure.

Our Blog