Polyethylene Coating Excellence

Unmatched Durability for Diverse Applications

Our polyethylene coating services offer unparalleled protection and versatility for a broad spectrum of applications. Recognized for its excellent chemical resistance, durability, and moisture protection, polyethylene is one of the most widely used plastics in coating technologies today. Our cutting-edge polyethylene coating solutions are tailored to extend the life of your products, ensuring they withstand the rigors of their application environments.

What is Polyethylene Coating?

Polyethylene is a multi-purpose, thermoplastic powder coating designed to meet a wide range of qualifications. As a general purpose coating, it rivals Vinyl in variety of uses but has a higher impact rating than Vinyl, offering superior durability and flexibility for applications demanding robust protection against environmental stresses and mechanical impacts.

Polyethylene Coating Applications

Common applications for Polyethylene include:

Common Specifications

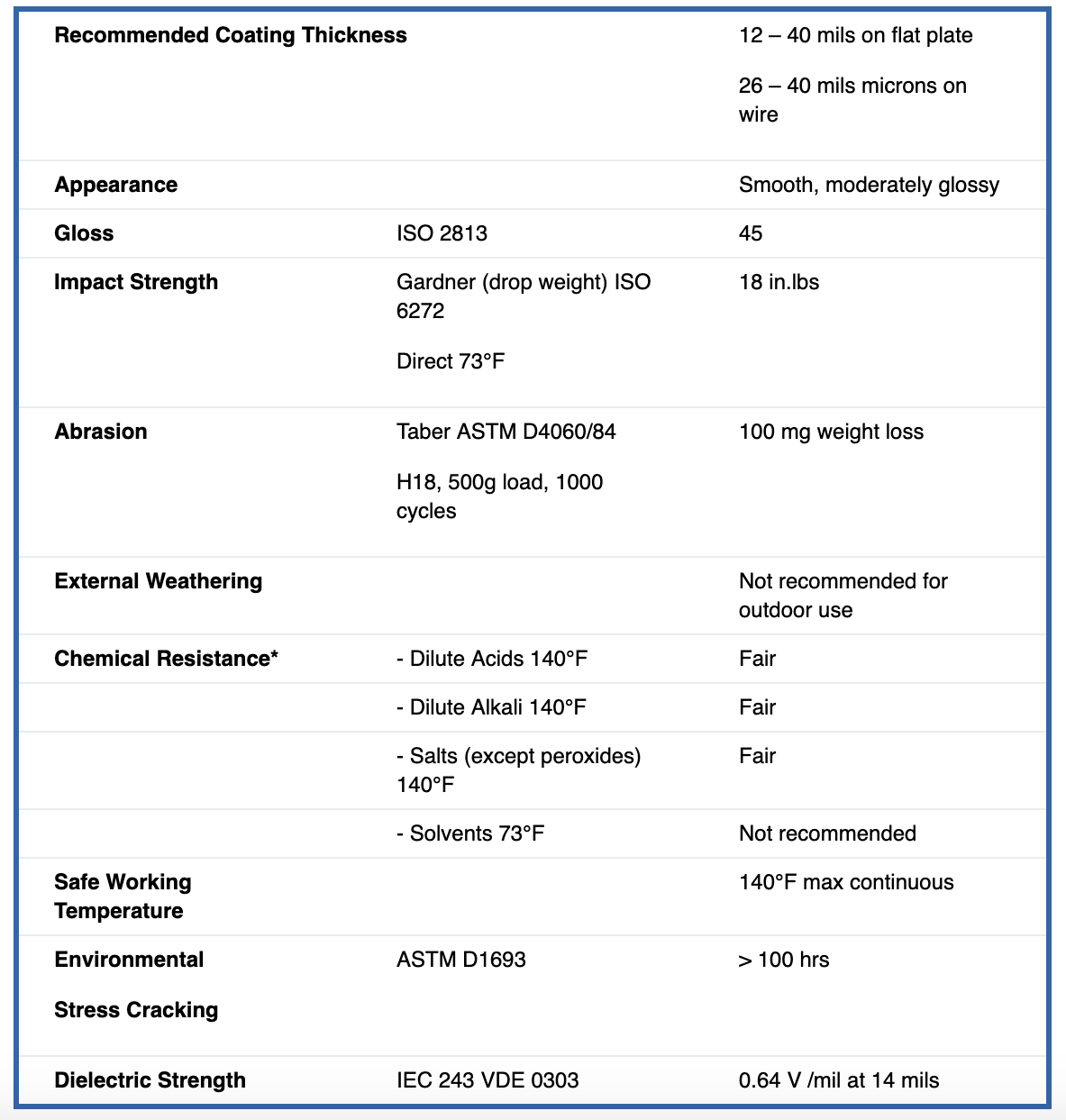

Below are common specifications for one of our Low-Density Polyethylene (LDPE) coatings.

* taken from Plascoat NG30 Specification Sheet

Partner with Us for Polyethylene Coating Services

Elevate the protection and longevity of your products with our state-of-the-art polyethylene coating services. Contact Precision Dip Coating today to learn more about how we can assist in enhancing your products with the durable, versatile, and eco-friendly benefits of polyethylene coating. Let us help you achieve the perfect combination of protection, performance, and sustainability.

Contact Us

Contact Us

Related Services

For more information about our manufacturing services, call us at 203-805-4564 or visit ourcontact page.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Frequently Asked Questions

What is polyethylene coating?

Produced most commonly in low-density (LDPE) and high-density (HDPE) types, polyethylene is part of the polyolefin family of thermoplastics. As a powder coating, changes in formulations offer a material suited to nearly any application and industry. Coatings are typically 12-40 mils (.012-.04 inches).

What makes polyethylene a desirable coating material?

One of polyethylene coating's most valuable qualities is its resistance to cracking under stress (ductility), but PE coating has more to offer, including:

- Abrasion and impact resistance

- Chemical and corrosion resistance

- Non-yellowing

- Low-temperature tolerance

- Durability

- Food-grade rating

- UV-tolerance (some formulations)

What industries use polyethylene powder coatings?

While polyethylene coatings are suitable for a wide range of applications, their approval for food-grade uses makes them especially popular for coating wire racks such as in refrigerators, dishwashers, freezers, and other food-storage and household environments. Polyethylene is durable enough to perform well in those applications as well as such diverse uses as landscaping equipment, railings, and sporting goods.

Is polyethylene coating safe?

Polyethylene is approved by multiple agencies for food-grade use, making it extremely safe. As such, it contains no BPA, phthalates, heavy metals, halogens, or other toxic components, and requires no solvents or VOCs to apply.

What colors are available for polyethylene coating?

Polyethylenes can be transparent to opaque, and many varieties are available in a spectrum of stock and custom colors.

Our Blog