Halar Coating Services

Unparalleled Protection for Industrial Applications

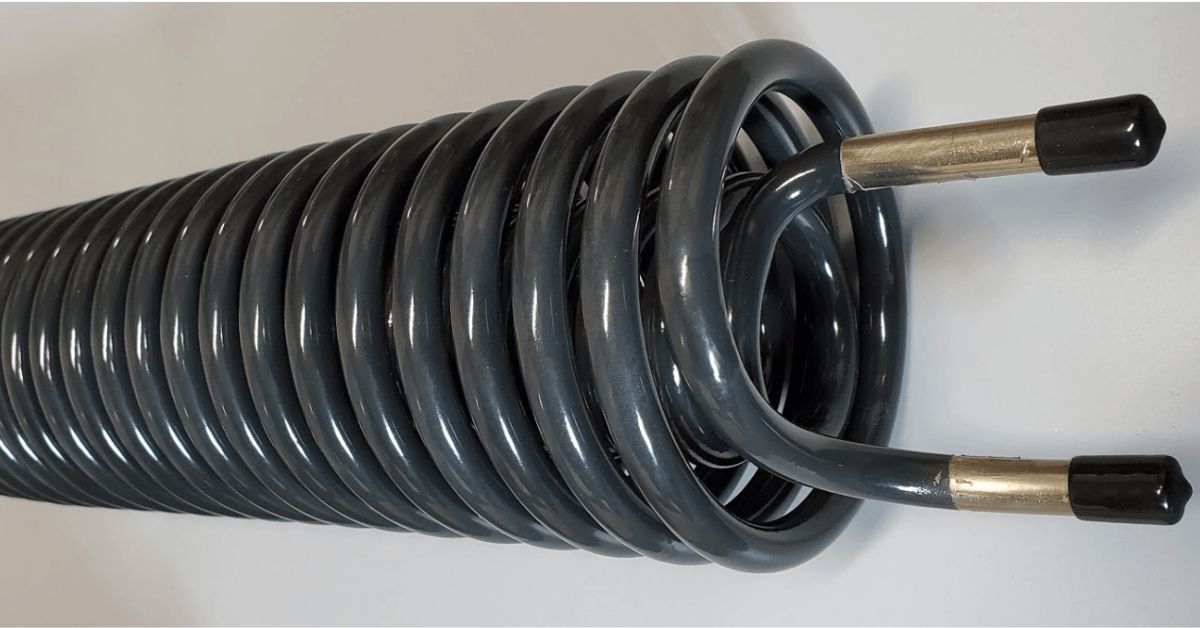

At Precision Dip Coating, we are proud to offer cutting-edge Halar coating services, a pinnacle of protective solutions for a wide array of industrial applications. Halar, the trade name for ethylene chlorotrifluoroethylene (ECTFE), stands out in the world of plastics for its remarkable semi-crystalline and melt-processable properties. Our expertise extends to leveraging Halar's unique benefits to enhance the durability, performance, and lifespan of your products.

Unveiling the Power of Halar Coatings

Halar ECTFE, a semi-crystalline fluoropolymer, is distinguished by its remarkable chemical resistance, durability, and surface smoothness. These properties make it an ideal choice for protective coatings, ensuring longevity and reliability of your products. Whether it's for the chemical, pharmaceutical, or microelectronics industries, Halar coatings provide a shield against harsh environments, maintaining the integrity and performance of your equipment.

Why Halar Coatings?

Here are the core advantages that make Halar coatings an essential choice for businesses looking to enhance their products:

Applications of Halar Coatings

The versatility of Halar coatings makes them suitable for a myriad of applications, including but not limited to:

Let's Get Started Today

Transform your products with the advanced protection of Halar coatings.

Contact Precision Dip Coating

today to discuss how we can enhance the durability and performance of your equipment. Our dedicated team is ready to bring your project from concept to completion with precision and care.

Contact Us

Contact Us

Related Services

For more information about our manufacturing services, call us at 203-805-4564 or visit ourcontact page.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Frequently Asked Questions

What industries use Halar coatings the most?

Several of the most common fields using Halar coatings include:

Medical and pharmaceutical

Industrial, including tanks and wire baskets

Semiconductors and microelectronics

Truly, any industry requiring its unique characteristics could benefit from its strengths.

Why choose Halar as a coating material?

Extremely resilient and smooth Halar coatings can help to reduce equipment wear and damage due to rubbing parts and exposure to electrical current, heat, moisture, and chemicals.

Is Halar the same as Teflon?

While they are related fluoropolymer materials, Halar (ECTFE) offers greater durability and an opportunity for thicker coatings than with Teflon (PTFE). Halar is stronger than Teflon, but one drawback is a lower heat tolerance.

What is Halar's greatest advantage for the medical industry?

Button

ButtonWith extreme smoothness reducing opportunities for bacteria and germs to take hold, along with high strength and resistance to moisture, chemicals, and impacts, Halar coatings are a natural match for improving safety and hygiene for medical applications.

Our Blog