Vinyl coating at Precision Dip Coating

Transform Your Products with Durable and Aesthetic Vinyl Coating Solutions

At Precision Dip Coating, we specialize in providing top-tier vinyl coating services designed to enhance the durability, functionality, and appearance of your products. With many years of expertise and a commitment to quality, our team ensures that every project meets the highest standards of excellence.

Different Applications of Vinyl Coating

Whether you are looking for flexibility, color or chemical resistance, Vinyl powder coatings can help you meet your goals. Fluid Bed Vinyl coating can be applied to a variety of substrates, and its versatility and cost effectiveness are unmatched. Diverse applications of vinyl coating include:

Vinyl is typically seen on items such as:

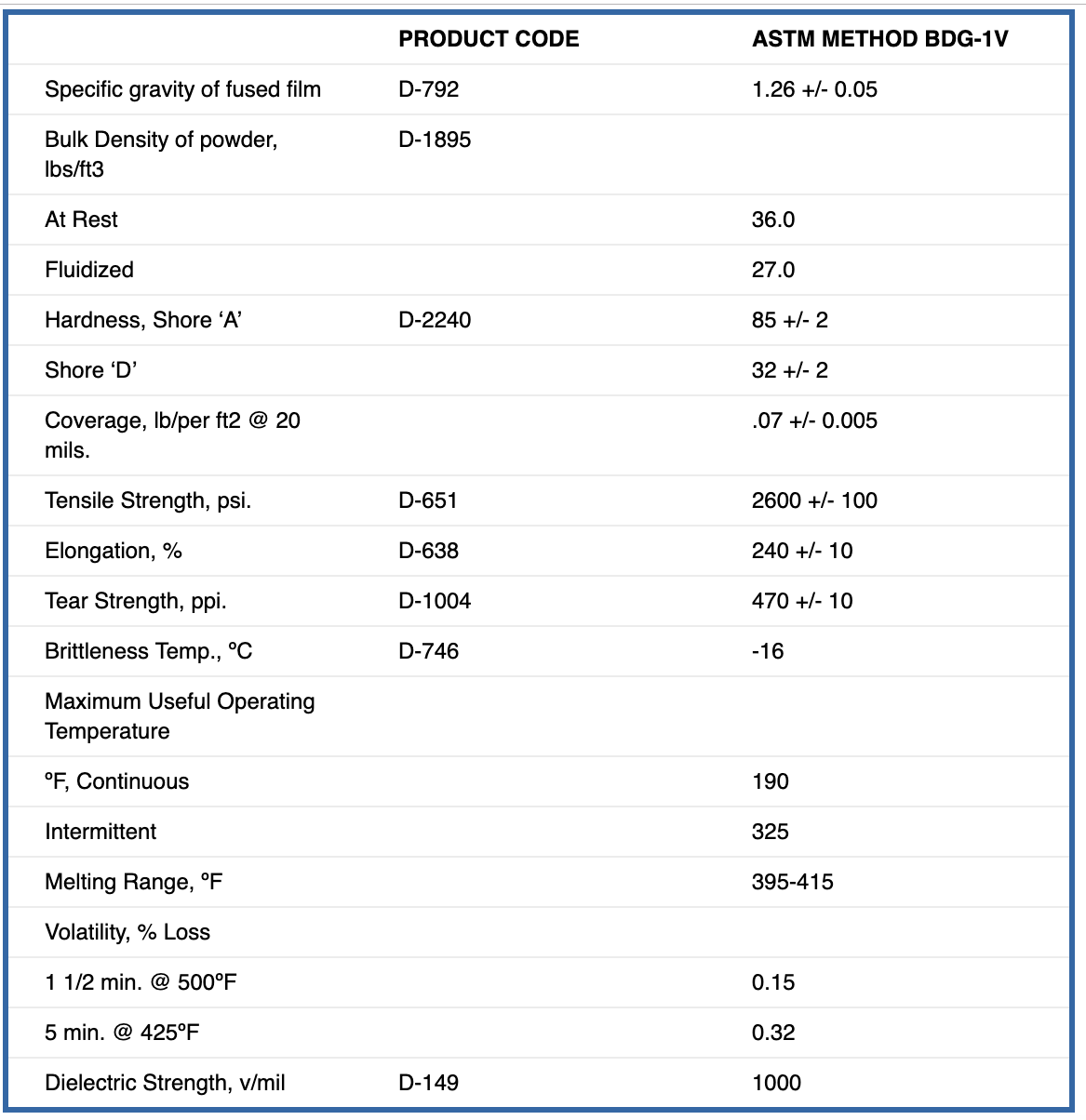

Common Properties of Workhorse Coating Material

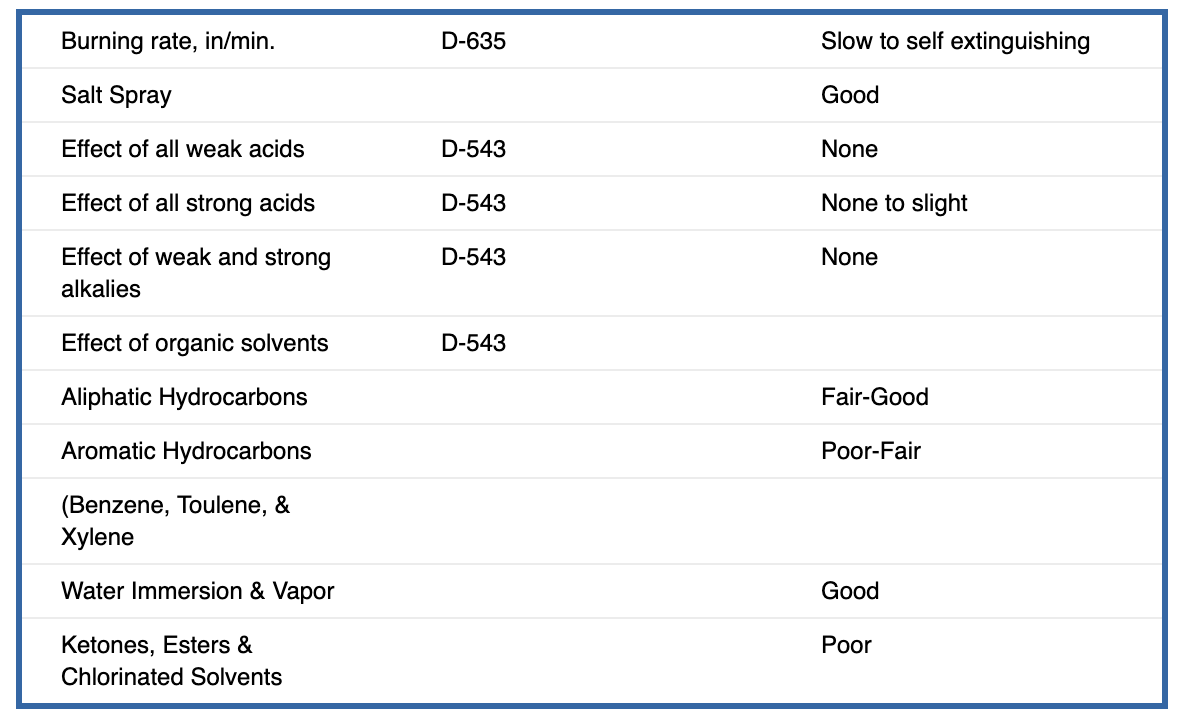

Resistance Characteristics

Salt spray resistance of all properly applied and primed DURAVIN vinyls is excellent; a zinc or iron phosphated substrate, primed with the recommended DURAVIN primer, and coated with the above products will provide a durable finish showing no effect in 5,000 hours of salt spray exposure; less than 1/8″ undercutting will be observed on a scored panel exposed for 2,000 hours. Vinyl coatings, as a rule, exhibit excellent chemical resistance to acids, alkalies, alcohols, gasolines and aliphatic hydrocarbons although concentration, temperature and the nature of the chemical does have a bearing on the degree of the coating’s inertness. Vinyls are not recommended for contract with aromatic hydrocarbons, chlorinated solvents or ketones.

Get Started with Us Today

Ready to enhance your products with high-quality vinyl coating? Contact us today to discuss your project. Our team is eager to collaborate with you to find the perfect coating solution that meets your needs and exceeds your expectations.

Contact Us

Contact Us

Related Services

For more information about our manufacturing services, call us at 203-805-4564 or visit our contact page.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Frequently Asked Questions

Are vinyl coatings safe?

Vinyl coatings need plasticizer components which allow them to achieve the flexibility they require. Traditionally, plasticizers often contained phthalates, which can be harmful to those exposed to them. Newer formulations of vinyl coatings can be phthalate-free, making them a safe choice.

What's the difference between vinyl, plastisol, and PVC?

Vinyl powder coating and plastisol are two different but related types of polyvinyl chloride (PVC)-based coatings. Plastisol is a liquid at room temperature and typically applied in thicker coats by dipping, while vinyl powder coating is normally applied in thinner coats by electrostatic spray or fluidized bed.

What are the most valuable characteristics of vinyl coatings?

Vinyl coatings offer excellent benefits for the products and surfaces they cover (and their manufacturers), including:

- Extreme durability

- Excellent insulating capabilities

- Superior resistance to chemical exposures

- High performance in a wide range of temperatures

- Powerful resistance to impacts and abrasions

- Low cost for value

What does vinyl powder coating look like?

Vinyl coatings have a shiny, glossy finish, and, like related plastisol coatings, can be tinted virtually any color.

What are some common applications for vinyl coatings?

Vinyl coatings are an excellent choice to protect wire goods and similar products, such as sports helmet facemasks, appliance racks and shelving, and industrial baskets. Playground equipment, outdoor furniture, and electrical components are also frequent candidates for vinyl coatings.

Our Blog