Polyolefin Coating: Superior Outdoor Protection

Durability and Eco-Safety for Exterior Applications

As industries advance and seek more sustainable, long-lasting protective measures, Polyolefin coating emerges as the clear choice for safeguarding a wide array of materials against the elements. Join us in exploring how this versatile coating can revolutionize your outdoor projects, blending performance with peace of mind.

What is Polyolefin Coating?

Precision Dip Coating

offers a durable hybrid Polyolefin coating ideal for outdoor use on mild steel, galvanized steel, and aluminum. This halogen-free alloy provides superior corrosion protection, low smoke and toxicity levels in combustion, and is UL94-V0 rated, making it an excellent choice for outdoor applications. It resists graffiti, stress cracking, weather, detergents, salt spray, and pollutants, adheres well to metal without primer, and offers good electrical insulation and resistance to abrasion and impact, outperforming Vinyl in many respects.

Common Applications for Polyolefin

Common applications for Polyolefin Coatings are:

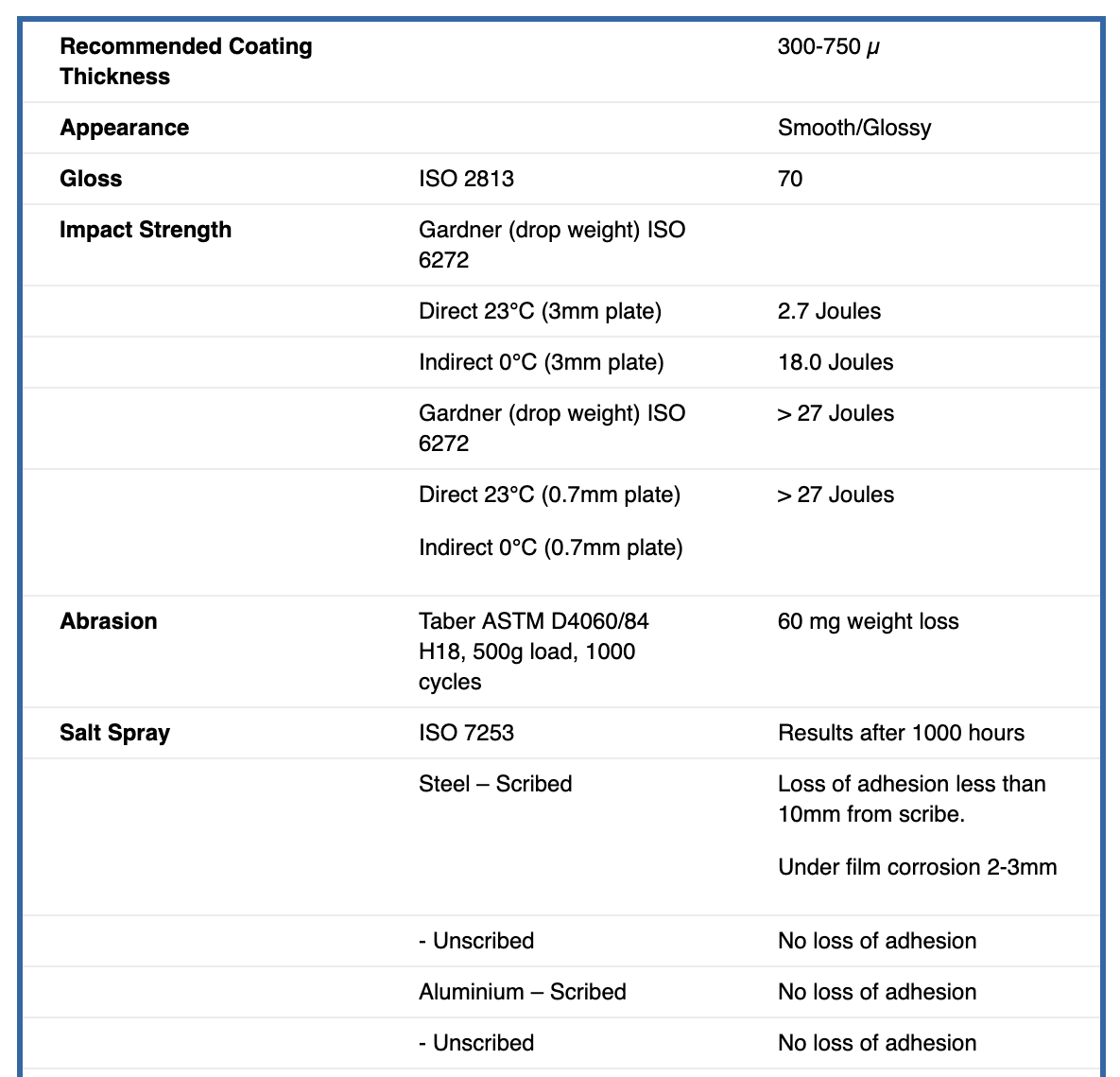

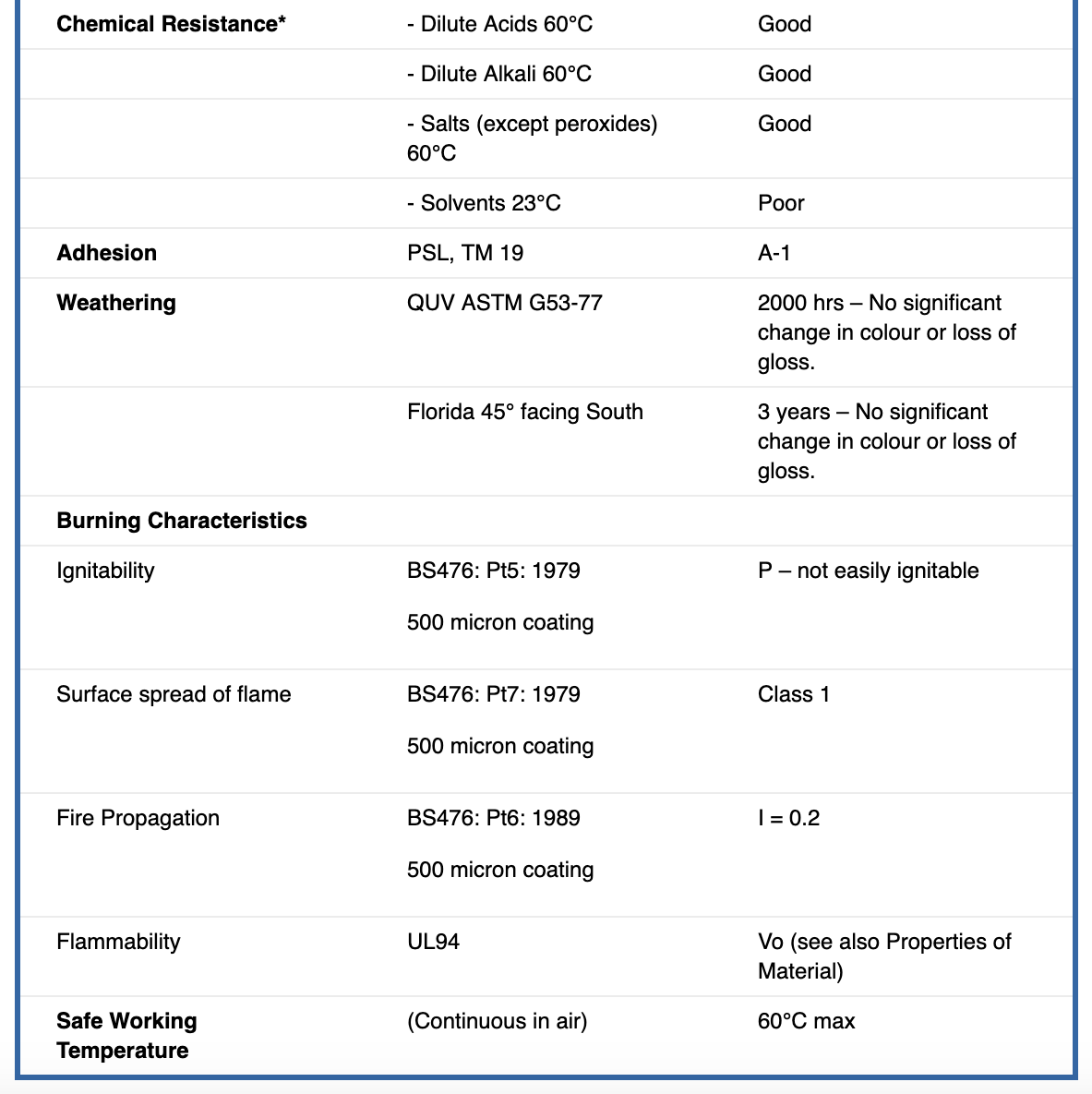

Common Properties of Polyolefin Coating

Below are the common properties of these Polyolefin coatings.

Embrace the Future with Polyolefin Coating

Precision Dip Coating's Polyolefin coating represents the pinnacle of outdoor protective solutions, combining durability with environmental consciousness. This advanced coating technology not only exceeds the performance of traditional materials like Vinyl but also addresses the growing need for eco-friendly, safe, and robust protective solutions. By choosing Polyolefin coating, you're not just enhancing the lifespan and appearance of your outdoor equipment and structures; you're also investing in a sustainable future, ensuring your projects stand the test of time while minimizing environmental impact.

Contact Us

Contact Us

Related Services

For more information about our manufacturing services, call us at 203-805-4564 or visit ourcontact page.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Frequently Asked Questions

What is polyolefin?

Polyolefin is the name for a family of polymers that include polyethylene (PE) and polypropylene (PP) plastics. Polyolefin coatings can be applied by fluidized bed or electrostatic spray techniques.

What makes polyolefin a good powder coating choice?

While polyolefin powder coatings can be used for many indoor applications, they are most frequently applied for outdoor use. Characteristics which make polyolefin an ideal outdoor coating include:

- Superior resistance to UV exposure

- High performance under temperature extremes, including as low as -94°F (-70°C)

- Excellent chemical and corrosion resistance

- Powerful bond between the coating and metal substrate

- Excellent resistance to common outdoor environmental hazards, including salt, sun, mold, mildew, algae, and seawater

- High resistance to cracks, peeling, abrasions, impacts, and chipping

- Glossy, attractive surface

- Stock and custom colors

What are some common uses for polyolefin coatings?

Frequent uses for polyolefin coatings include:

- Playground equipment

- Benches and other public seating

- Bike racks

- Waterfront fencing and railings

- Lampposts and other street and sidewalk fixtures.

Is polyolefin eco-friendly?

The polyolefin coating formulation we use requires no primer, so it is free of VOCs. In addition, it contains no BPA, phthalates, halogens, or other toxic ingredients.

Is polyolefin coating durable?

Testing shows that reliable, long-lasting polyolefin coatings should perform well for at least:

- 70 years in traditional settings

- 200 years in underground applications

- 5 years for marine and heavy industrial uses

Our Blog